Beam Coping Machine Dimensions

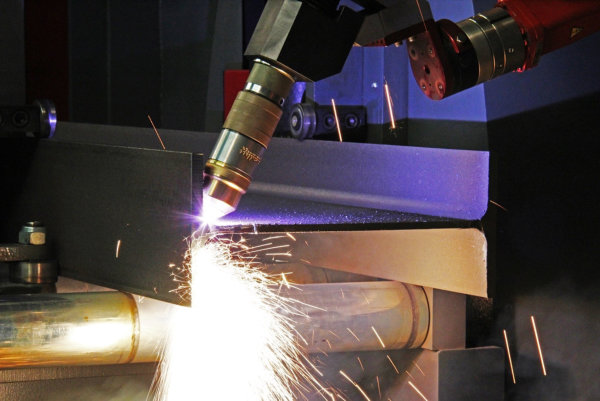

This safety mechanism ensures long tip and head life as well as significantly increasing up time to avoid costly torch tip changeovers and repairs.

Our top-of-the-range coping/profiler robot makes 3D coping and profiling much easier. These Robotic Coping beams and Profiling beams not only work well, but they can also be used to cut slots, chamlers, and saddles.